Page 1 of 3

DIY HPA route? (Diaphragm pump?)

Posted: Tue Nov 24, 2009 3:17 am

by CS

^Trying to get some decent air pressure for small caliber launchers, I'm thinking 500-1,000 PSI.

Had a multiple stage compressor (standard piston setup) in the plans, but was reading up on Stirling engines today, and in short I came across the

diaphragm pump article.

Then this:

gas compressor wiki wrote:The photograph included in this section depicts a three-stage diaphragm compressor used to compress hydrogen gas to

6,000 psi (41 MPa)

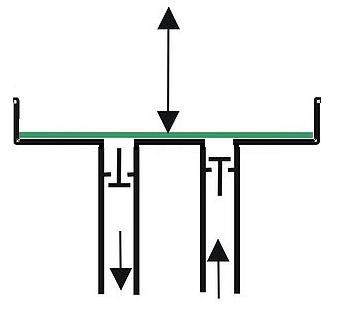

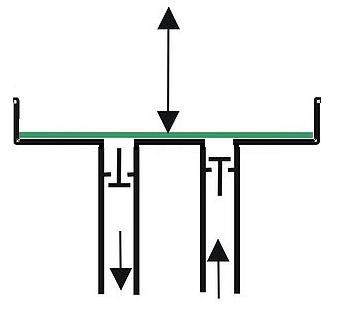

To reduce the surface area on the membrane, a flat plate could be attached similar to

this.

Still working on the idea myself, but thought I'd pitch it...

Posted: Tue Nov 24, 2009 3:24 am

by inonickname

It strikes me that it would be difficult to keep dead space low. Fluids are not compressible so there is little issue with having amount of dead space though air is and it could certainly be a problem.

Posted: Tue Nov 24, 2009 3:37 am

by CS

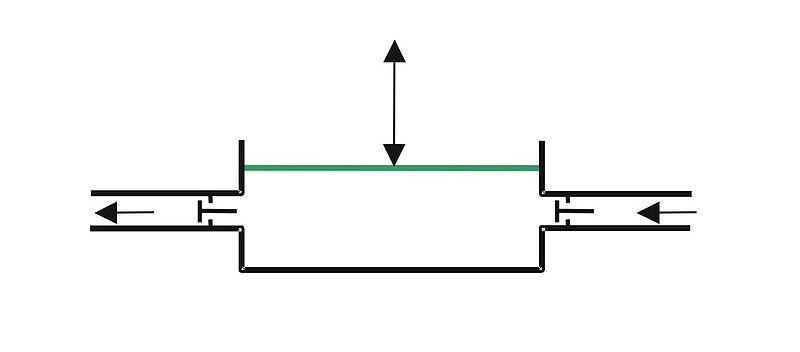

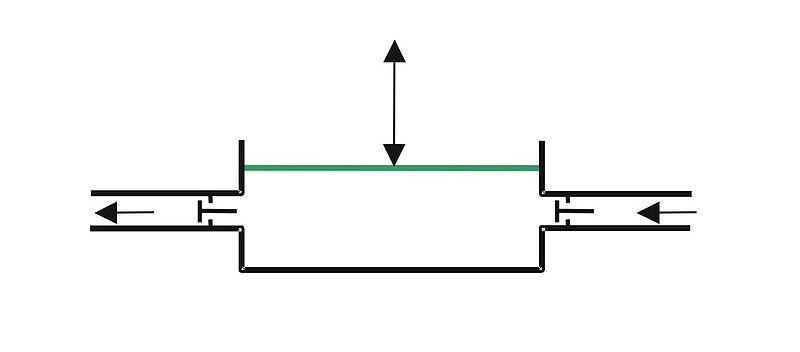

From this:

To this:

Posted: Tue Nov 24, 2009 5:45 am

by inonickname

So the function is the same as a piston compressor, except that the piston is supported by a flexible material. It would probably still be difficult to keep dead space low, unless there was a seal around the solid disc. In that respect, it would be a piston valve with a short stroke.

Do you plan to use a small bore and long stroke, or short stroke with large bore and a lever?

Posted: Tue Nov 24, 2009 6:52 am

by iknowmy3tables

I'm not sure what you meant by

a flat plate could be attached similar to this

do you mean a plate backing the diaphragm to prevent bulging, or a general flange construction

my experience with diaphragm compressors was some sort of paint sprayer compressor, it operated on a giant solenoid, it had a nice flow rate but had a peak at 40psi, and vibrated like crazy

about the dead space, you can probably fill it with epoxy, oh and btw mcmasters has tensile pressure rating for some sheet rubbers

how were you planing to power the diaphragm?

Posted: Tue Nov 24, 2009 7:52 am

by inonickname

He says small caliber, so I'd assume around the .22 range. If it's only a single shot or a low number of shots you desire I'd just make a pump which has a moderate bore and a lever to make pumping easier, similar to the slim jim pump used in brocock cartridges or a hydraulic pump.

You could probably modify an old hydraulic jack bottle pump with some work.

Posted: Tue Nov 24, 2009 8:10 am

by POLAND_SPUD

So the function is the same as a piston compressor, except that the piston is supported by a flexible material. It would probably still be difficult to keep dead space low

I think it would be more difficult to reduce dead space with a diaphragm

and I get the impression it would be more difficult to build it when compared with a piston compressor

I know that someone will mention it sooner or later but you might build a pressure amplifier instead. I suppose that you have a shop compressor, right ?

well you would just have to build a stirrup pump with extremely low piston area and hook up an air cylinder to it... then just add two DCV to automatically retract and extend it and voila! - you've got a pressure amplifier

Posted: Tue Nov 24, 2009 9:02 am

by iknowmy3tables

I think it would be more difficult to reduce dead space with a diaphragm

I don't think that's necessarily true, however with the tiny volume of a diaphragm the dead space is going to matter a lot more

If your going to try this you should probably machine the check valves in a way to reduce dead space

Posted: Tue Nov 24, 2009 9:48 am

by psycix

Diaphragm pumps only work well with non-compressible fluids, so no gases.

For high pressure, a piston with a long stroke may be easier to accomplish.

There is only one way in which they are better: they can't leak around the piston.

When going 500+ psi, I think two-stage is the way to go.

Posted: Tue Nov 24, 2009 10:16 am

by POLAND_SPUD

well I think that my idea is probably the simplest way to build a HP compressor

and it can be built without machining... you could even use a ready made PCP pump if you have one or if you can buy one cheap

to make the setup more practical you'd need a HPA tank (or tanks) that you can pump with it... of course you'll also need a small filling station with gauges, a pop-off valve (better yet two valves and/or burst disk) and a cooling system...

with a setup like this you wouldn't need to worry about flow - you could turn the compressor on and let it pump the tank/tanks while you do something else

Posted: Tue Nov 24, 2009 10:29 am

by inonickname

On the subject of commercial PCP pumps, does anyone have a diagram of a multi stage PCP pump? I understand the function of a multistage pump, though I can't quite figure how to integrate it into a single cylinder.

Posted: Tue Nov 24, 2009 12:24 pm

by kenbo0422

A tube with a thick wall inside a cylinder. The tube is blocked on one end, with a check valve. The other end is plugged with a rod... Well, look at the drawing...

Posted: Tue Nov 24, 2009 4:03 pm

by CS

inonickname wrote:Do you plan to use a small bore and long stroke, or short stroke with large bore and a lever?

Initially air would start in a low pressure stage (large bore, short stroke) then move into progressively higher pressure stages (small bore, long stroke).

iknowmy3tables wrote:do you mean a plate backing the diaphragm to prevent bulging, or a general flange construction

how were you planing to power the diaphragm?

My thought is it would reduce the surface area of the membrane, while still utilizing the flexibility of the membrane.

Crankshaft, multiple stages. Got a 1HP motor with a 60:1 gearhead on it.

psycix wrote:When going 500+ psi, I think two-stage is the way to go.

HP for 1 CFM

2-stage-500 PSI output, cylinder ratio: 5.91, .342 HP

3-stage-500 PSI output, cylinder ratio: 3.27, .327 HP

3-stage-1,000 PSI output, cylinder ratio: 4.11, .383 HP

3-stage-1,500 PSI output, cylinder ratio: 4.69, .43 HP

^15% friction added to the theoretical HP.

jimmy101 wrote:You could make a 1000 PSI compressor from small id pipe and a suitable piston. With a 1/8" cylinder it would take just ~12 pounds of force and a ~70:1 compression ratio to get to 1000 PSI.

So now that I've been nudged off diaphragm pumps, back to piston style pumps. BTW, my interest is not to manually run pumps, so no shock pumps.

kenbo0422, that is a great idea. Now so I don't get any exercise,

biggie size it?

Posted: Tue Nov 24, 2009 4:27 pm

by Brian the brain

You know I like high pressure...but I want to urge you to be careful with this.1000 psi of air is very unforgiving.

I'd say: get a fridgepump and put a bigger motor on it.

Not easy enough?

Okay..

Just feed one with a regular compressor or a second fridgy.

Mine does 800+ psi on it's own..

Feed in 100 psi and the end result goes up significantly.

The outer shell is capable of handling more.

It even puts less strain on the piston, wich recieves a little extra help from the bottom, while compressing the air above it.

It will make you reach the desired pressure faster and go higher.

Linear pumps and motors are pretty hard to combine..

Posted: Tue Nov 24, 2009 4:31 pm

by POLAND_SPUD

so no shock pumps

and

biggie size it

whether you like it or not building a homemade HPA compressor from scratch is not exactly the simplest & cheapest thing (think machining)

but the design I proposed is quite simple to build... all you need is a sort of shock pump and an air cylinder to drive the piston of the pump up and down

sure it might not be the most efficient way but the biggest advantage of this design is it's simplicity...

Feed in 100 psi and the end result goes up significantly

maggotman claims that he has done that and it worked... but I've discussed this with jimmy and now I am not sure myself if it will work or not